ARISTA focus on Pharmaceutical Industry and GMP Environment. HMI Station and Clean Room operate well by ARISTA Hygienic Design IP66 Stainless Steel Products

You will find ARISTA Corporation has all computing platforms for either manufacturing process automation or KPI visualization in every process in the cleanroom. Our computing and display solutions are built with SS316L NEMA 4X / IP66 stainless steel enclosure to meet the highest hygiene requirements in pharmaceutical industries.

Mobile Pharmaceutical Workstation

Industry 4.0 is putting pressure on every sector to compete aggressively by accelerating their processes and advancing their core technologies to keep up with the competition. This creates a serious issue for resource-intensive fields like pharmaceutical research, development, and manufacturing. It is critical that every technology, every process, and every tool is leveraged to maximum performance capability. more

Multi Touch Technology and HMI

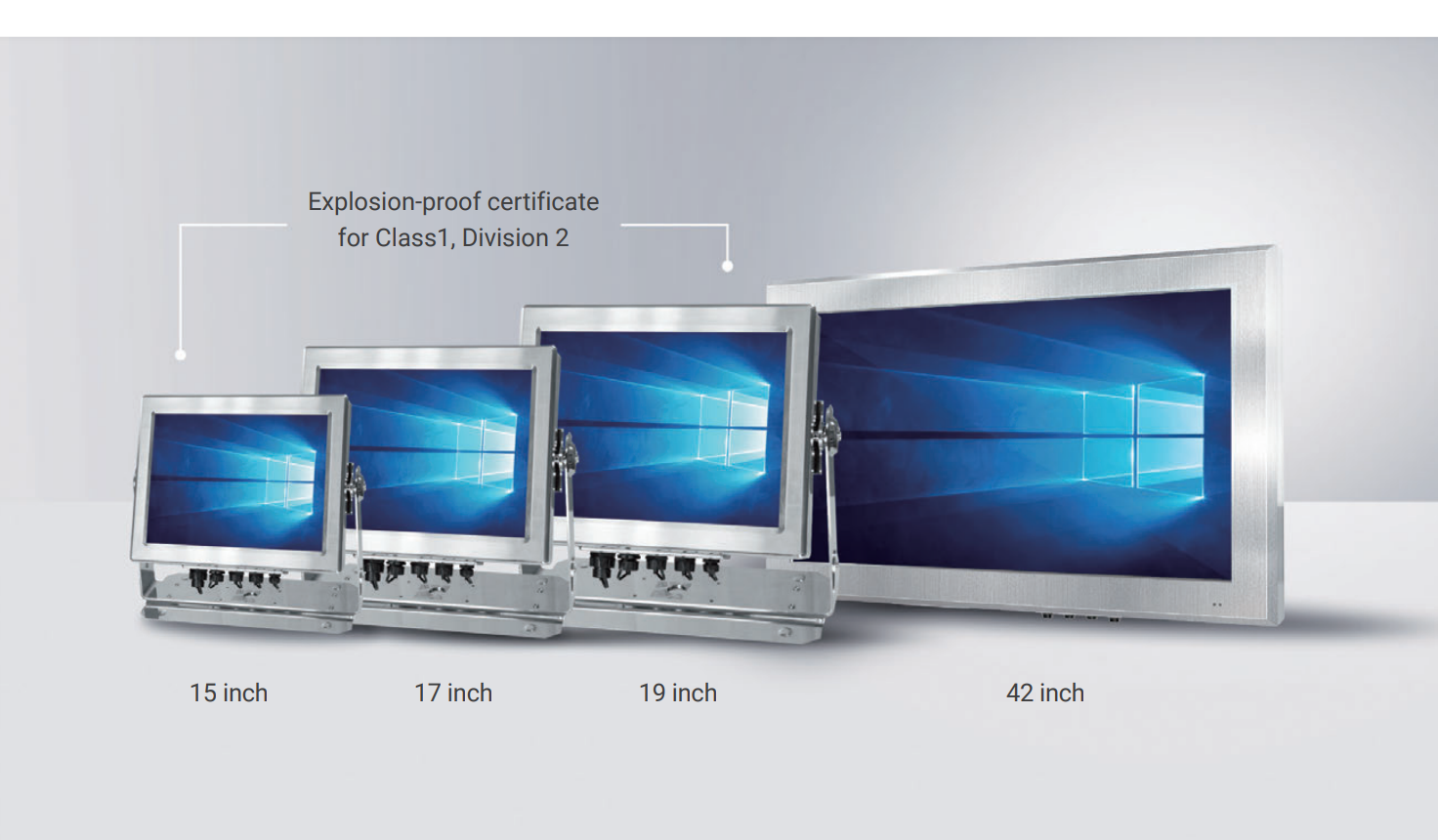

Class1 Division2 Industrial Panel PCs

ARISTA is a leading provider of Rugged Computing Platforms and Audio Visual Solutions

ARISTA’s Thin Clients and KVM extenders have been widely deployed in various industries, and we have boldly transformed to create value for our customers. With our two core business platforms — Rugged Computing Platforms and Audio Visual Solutions, we can bring the solutions to address the challenges of increasingly complex process automation for industrial harsh manufacturing environments.

Market Focus

We provide off-the-shelf, full turnkey integration services, and custom ODM/OEM design and development services for the Industrial Automation, Food & Beverage, Pharmaceutical, Oil & Gas, Wastewater Management, and Control Room marketplaces. Our ODM/OEM capabilities help our customers meet exacting specifications and requirements at an affordable price and quick time to market in harsh operating environments.

Manufacturing & Support Capabilities

All of our products are assembled and tested in our facility in Fremont, CA, undergoing stringent quality oversight enabling Arista Corporation to provide a two (2) year depot warranty for all computer products and three (3) year depot warranty for all display products. We work on the embedded long roadmap enabling 5+ years of continuity of supply and support, complemented by a comprehensive stringent revision control process.

Our Core Values

In a continuous pursuit of excellence, our core values include Innovation, Reliability, Agility, Integrity, and Trust. ‘Talk to us. We listen.’ We listen to our customers. We then apply creativity, technology, engineering, and manufacturing expertise to provide the optimum solution. We listen so we can continuously improve our products, processes, and services. We listen because our objective is to work in partnership with our customers to establish a long-term successful relationship.

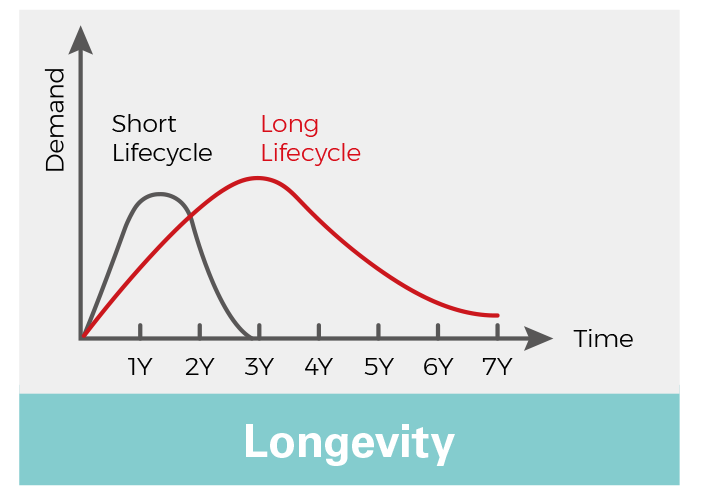

In the pharmaceutical industry, high reliability and stability are crucial. ARISTA‘s products guarantee a long product life cycle of 5-7 years, which allowing pharmaceutical manufactures not to worry about revalidating the replacement in the critical manufacturing process.

In the pharmaceutical industry, high reliability and stability are crucial. ARISTA‘s products guarantee a long product life cycle of 5-7 years, which allowing pharmaceutical manufactures not to worry about revalidating the replacement in the critical manufacturing process.