Abstract

This technical white paper addresses primary specifications and classification of hazardous area/hazardous locations safety issues, industry regulations, and security standards across the globe. This white paper will also give insight on class 1 division 2 and zone system particularly for chemical, petrochemical, and other similar industries where explosion-protected equipment is a necessity. With a focus on maintaining a completely safe industrial working environment, this paper will provide information on ARISTA’s UL class 1 division 2 certified non-incendive, corrosion-resistant thin clients industrial panel PCs, touch panel PCs, specifically designed to be used in chemical, petrochemical, food processing, cold storage pharmaceutical, and another harsh industrial environment.

Introduction

The complexity of today’s industrial automation needs, demands a safe and secure working environment. In certain industries, the manufacturing, processing, or storing flammable materials release gases or vapors in the atmosphere which can result in an explosion or hazard. To ensure a high level of security in these areas, most of the countries have outlined laws, regulations and guidelines. Manufactures and end users are required to comply with security regulations to avoid any hazard.

Understanding the tough industrial needs ARISTA’s talented team of engineers focus on the safety essentials and comply with electrical equipment regulations according to hazardous classified locations and different country’s standard. ARISTA works very hard over every certification and testing center for the design and manufacturing of equipment.

What is an explosion?

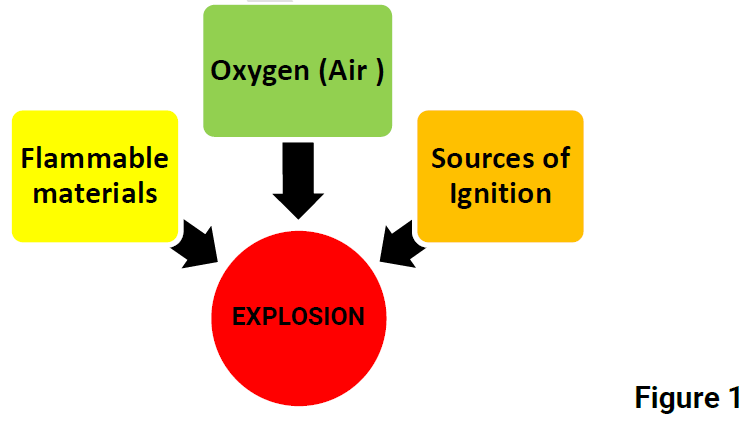

An Explosion is a sudden expansion involving physical or chemical decay with a rapid increase in pressure, resulting in a heavy blast and shock. In a chemical explosion, a molecule decomposes into combustible gases produced at a very high temperature. For an explosion to take place three factors which are flammable materials, air (oxygen) and ignition sources have to be present in sufficient quantities in the atmosphere.

Refer to figure 1 below:

An explosion does not occur only in the presence of flammable materials, there should be a sufficient quantity of flammable materials present for any hazard to occur. However, there are plenty of classifications and requirements that fall under the hazardous zone and their level of severity. Country-wise regulations with detailed explanations are listed below.

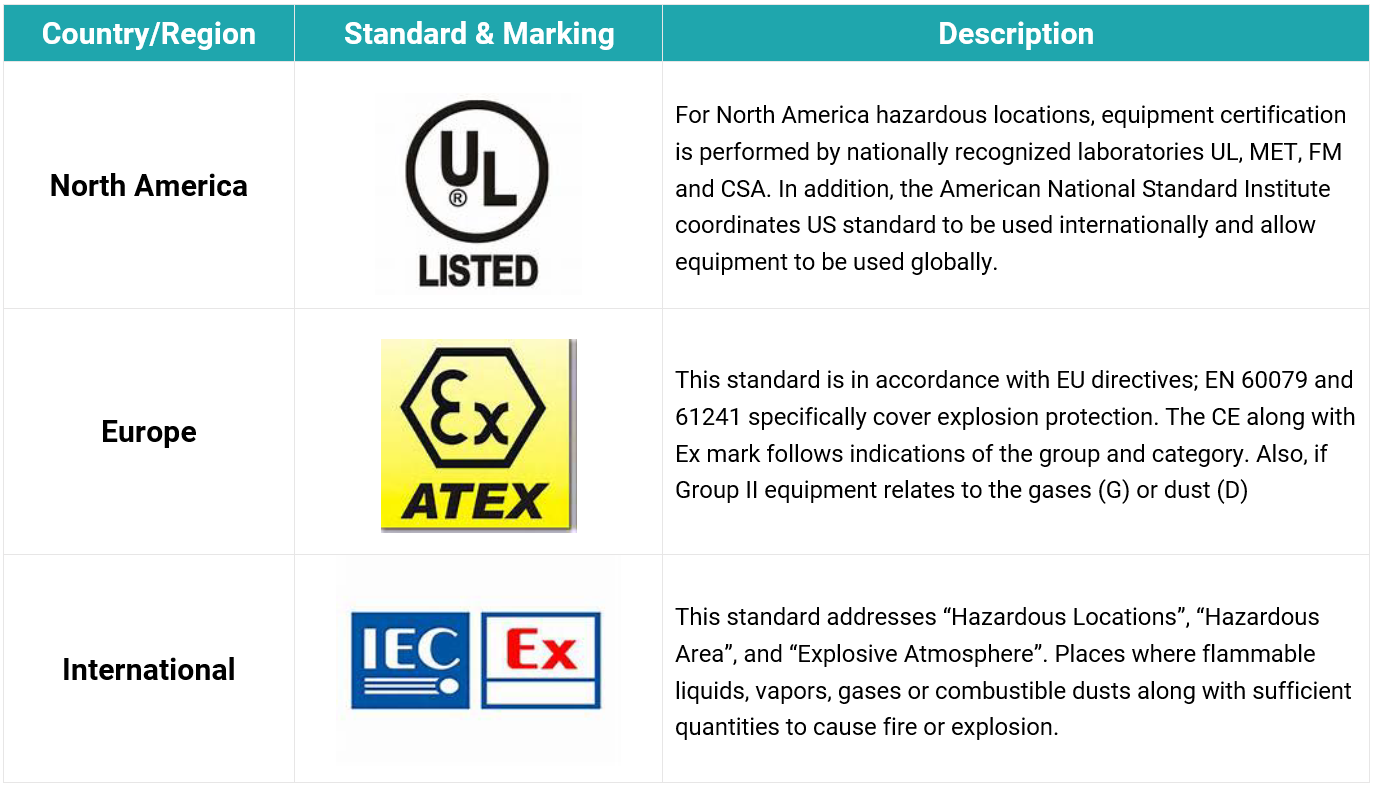

Design Regulations for anti-explosion electrical industrial automation equipment

Regulations are specifically meant for equipment to be used in hazardous locations defined by law. However, these might vary according to location, country laws, and other factors. Equipment not pertaining to regulations can counter delay in their shipping and face legal and liability issues. Regulations for the Class/Division system are formulated by NEC, CEC, OSHA, and NFPA (National Fire Protection Association). It is mandatory for every manufacturer to adhere by compliance, these are monitored by UL and other testing groups as mentioned above. After the equipment pass test, they are provided with a certificate stating; "explosion protection safety conditions are met and they are secured to be used for production".

The non-Incendive standard defined for Electrical equipment

International Society of Automation (ISA) and the American National Standard Institute (ANSI) have defined the non-incendive standard for electrical equipment to be used in hazardous locations. These standards provide design, construction and electrical marking requirements to be used in Class I and Class II, and Class III, Division 1 and 2 hazardous locations.

Hazardous zone and their classification

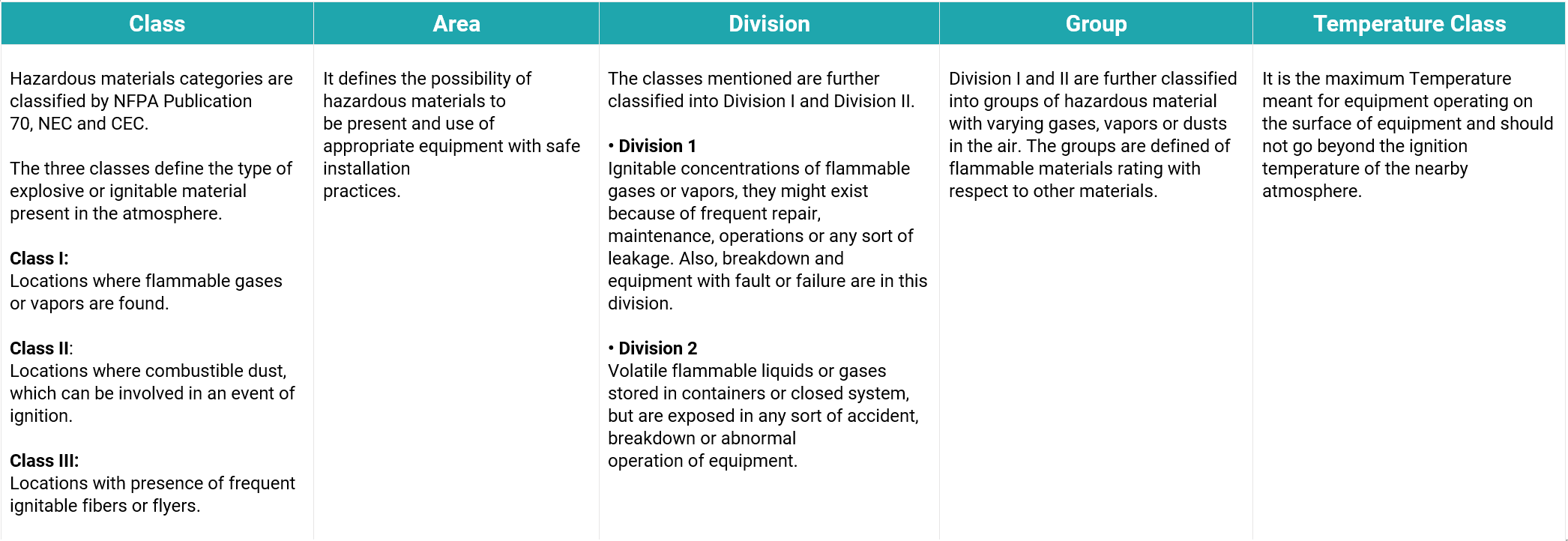

In simple terms, a hazardous classified location is any area, building, commercial or industrial premises that are likely to be exposed to fire or explosion due to the presence of flammable gases, vapors, flammable liquids, combustible dust, and other similar things in the very high amount. Hazardous locations can be classified into various categories according to the nature of flammable vapors or liquids. These categories can be defined by classes and classified by NFPA Publication 70, NEC, and CEC. Below is the classification of locations and division, which define the type of explosive or ignitable substance present in the atmosphere.

Class Definition: North America Classification System

In the United States and North America, manufacturers, in general, follow standards set up by the National Electric Code (NEC). Other popular classifications are NFPA publication and CEC. These benchmarks along with NEC specify the type of hazardous materials based on class, division, and groups. Class/Division standards are the primary methods catering to the design and manufacturing of industrial equipment across North America. The in-depth classification is widespread but it addresses all aspects of explosion protection and safety measures best practices. All these classes are categorized as per different explosives or ignitable substances that are found in the Atmosphere. The intent of this paper is to focus primarily on Class I Division 2 locations and its further classification.

Refer to the brief explanation and description below for the North America Classification system.

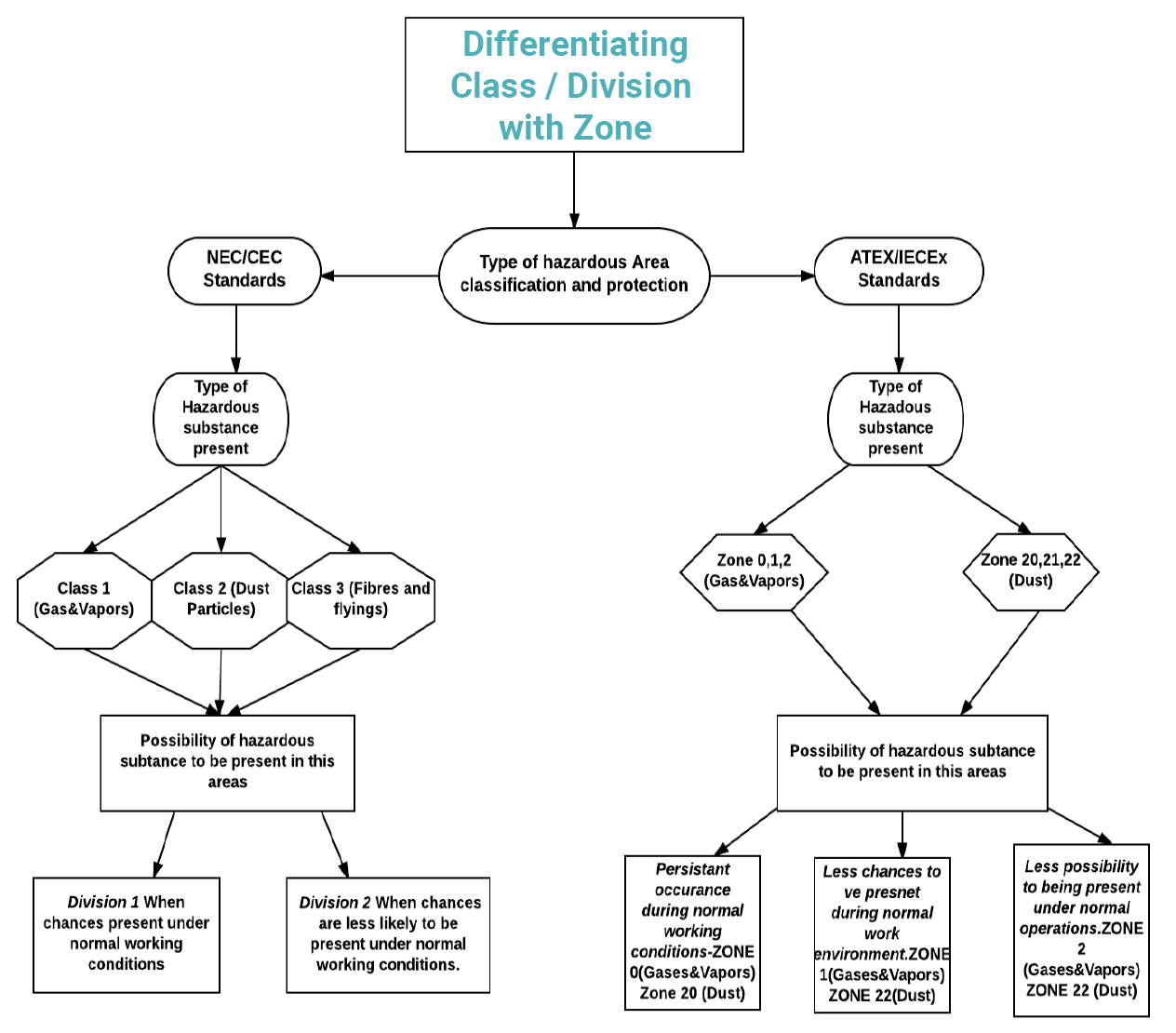

Zone System Classification

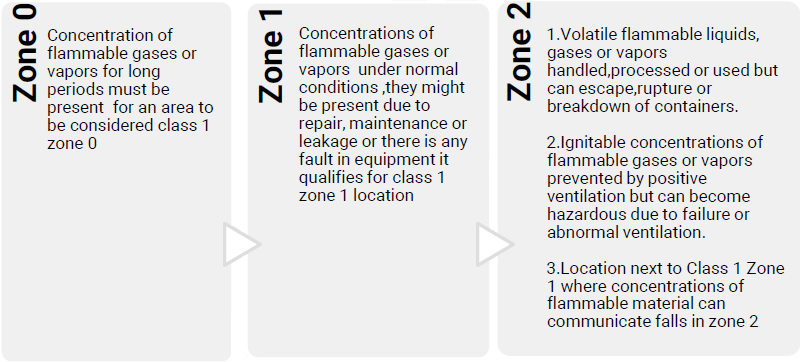

As discussed above Class/Division system is specifically used in North America for the purpose of regulating and defining hazardous locations for equipment safe handling and installation. However, outside of North America, the zone system is being used as a primary source of equipment in manufacturing and installation. The Zone system is quite similar to the class/division system; it defines and categorizes hazardous areas and potential risk sources.

Refer figure 2 for a detailed classification.

Figure 2

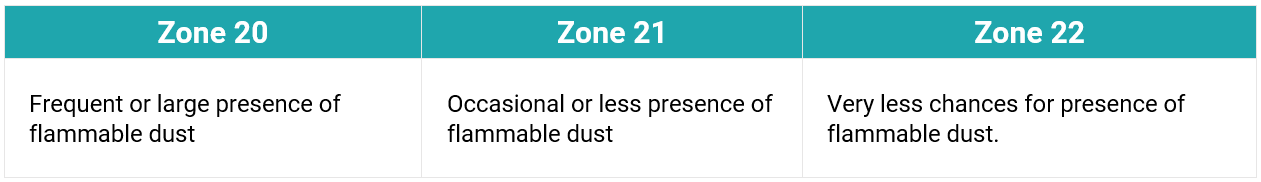

Likewise, there are other zones that cover potential flammable dust hazard, refer to the table below:

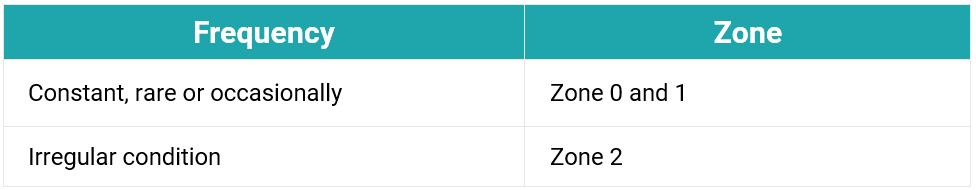

To get a clearer picture, the frequency of occurrence of an event determines the hazard level of that location. Hence, the more flammable materials are present in the atmosphere the more are chances for an explosion to occur.

Refer to the table below:

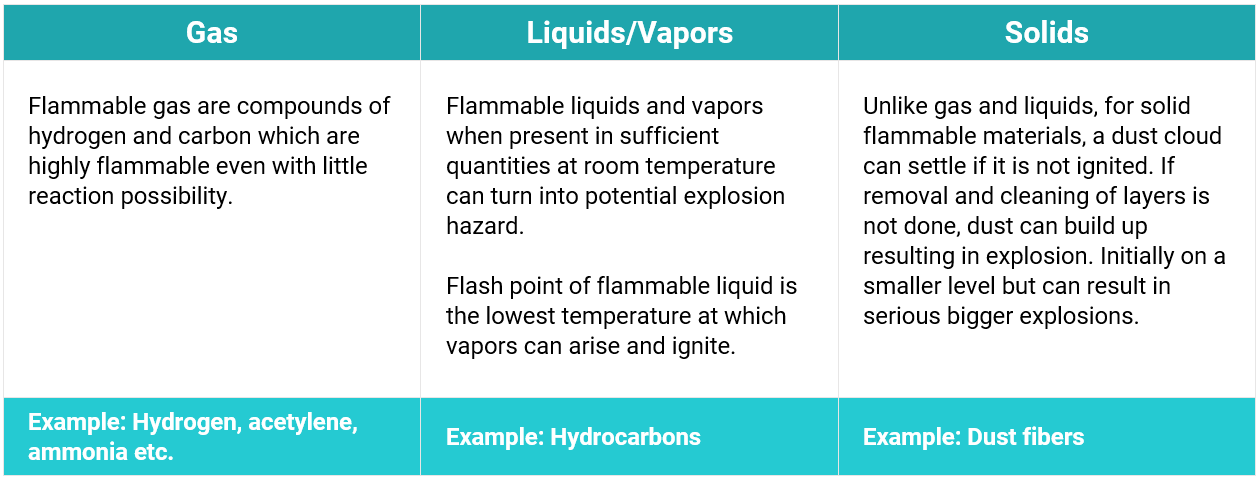

In addition, it is important to understand how the flammable substances/materials are categorized and how to get a better understanding of each of them.

Refer to figure 3 below:

Flammable substance

Figure 3

Note: Ignition or explosion can only occur when flammable gas, liquid, or solid material have their lower and upper flammability limits. Hence, not necessarily the presence of flammable material will result in a fire hazard.

Temperature Class definition and explanation:

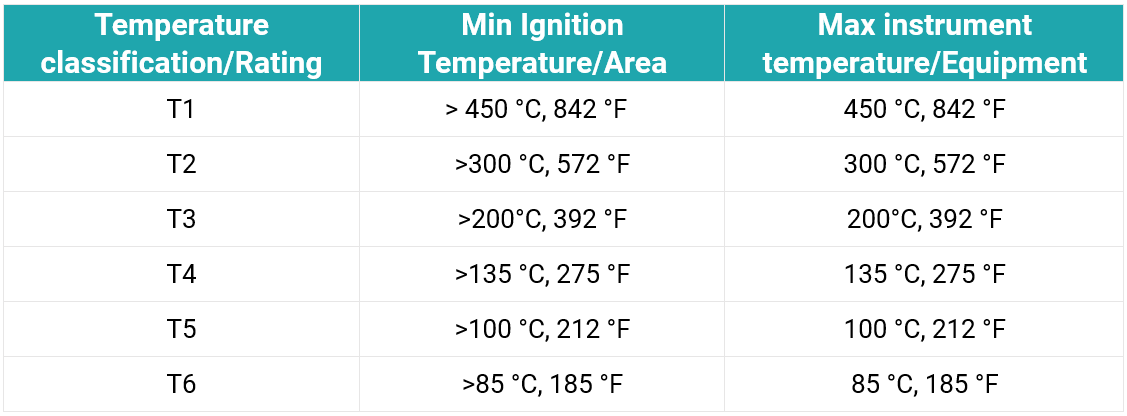

Equipment used in the hazardous area is assigned to a temperature class that defines the maximum surface temperature the device can go. In particular, this temperature should not exceed the ignition temperature of the atmosphere. With the minimum presence of ignition temperature even in normal atmospheric pressure a spark or flame is able to set fire or combustion or independent heating of the element. The dedicated rating for a temperature class also helps in preventing combustion that is dependent on the combustion point of the material present in that area.

Temperature classification is given to hazardous areas and temperature class ratings are applied to instruments. Values for the temperature classification range from T1 to T6, where T1 implies a minimum ignition temperature (>450° C [842°F) and T6 has a minimum ignition temperature >85°C [185°F]. Temperature class rating, this relates to the maximum temperature instrument is supposed to produce typically at a 40°C environmental temperature. However, this might vary in reference to other ratings.T1 thru T6 is used in temperature class ratings, where T1 is the maximum temperature generated by the instrument at 40°C is 450°C and T6 is the maximum generated by the instrument is 85°C.

Refer to the table below for a detailed view:

Differentiating Class/Division system with their Zone system

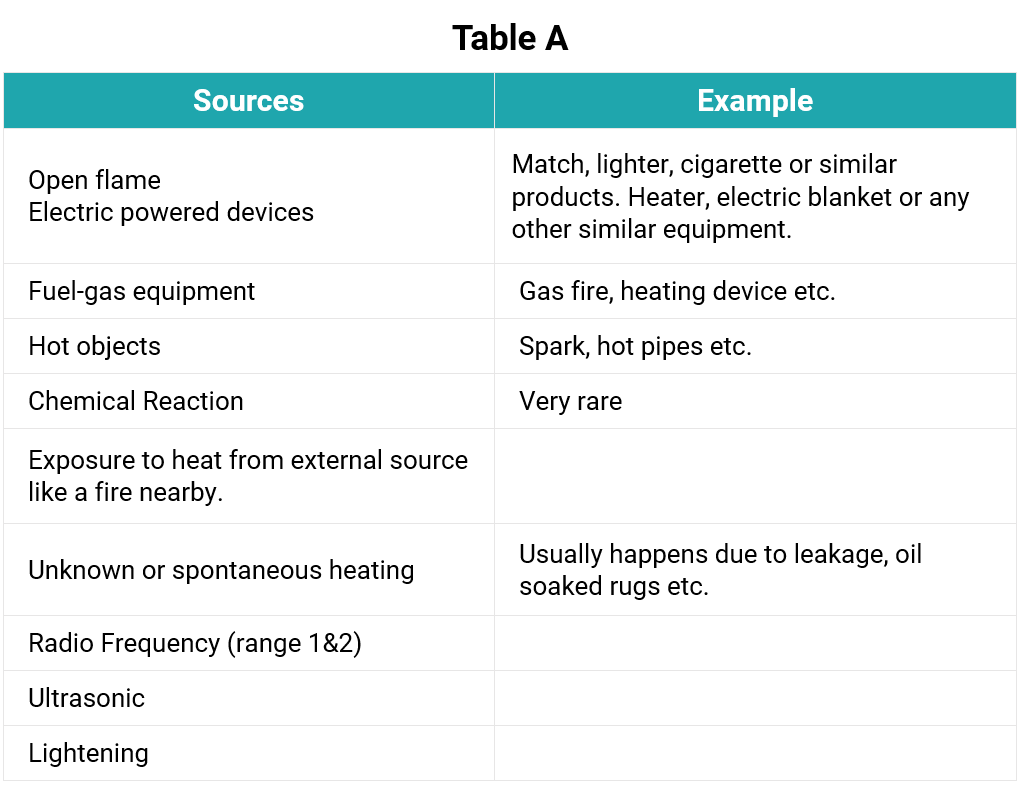

Sources of Ignition

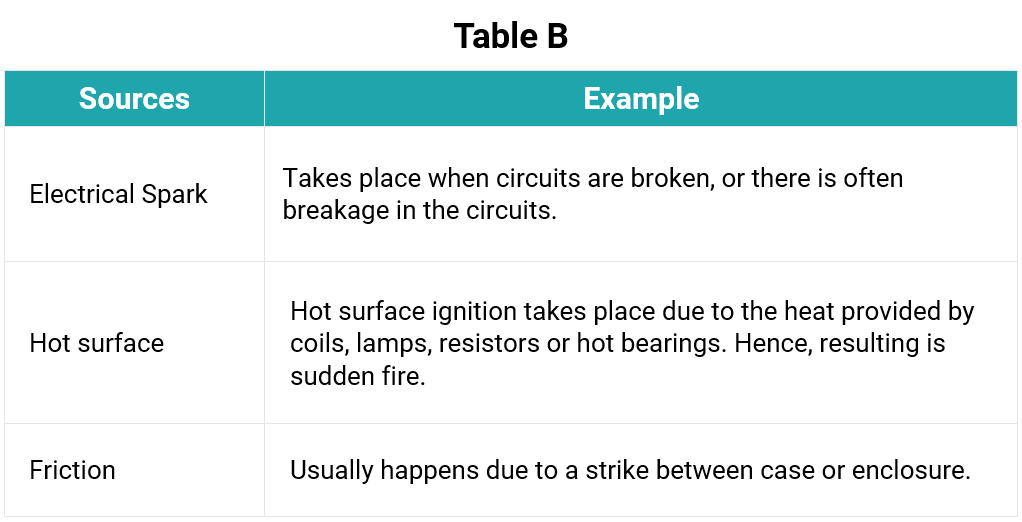

It is also important to know what sources can initiate a hazard, below is the list. Table A provides a general source of the ignition while table B shows ignition sources from industrial electrical equipment.

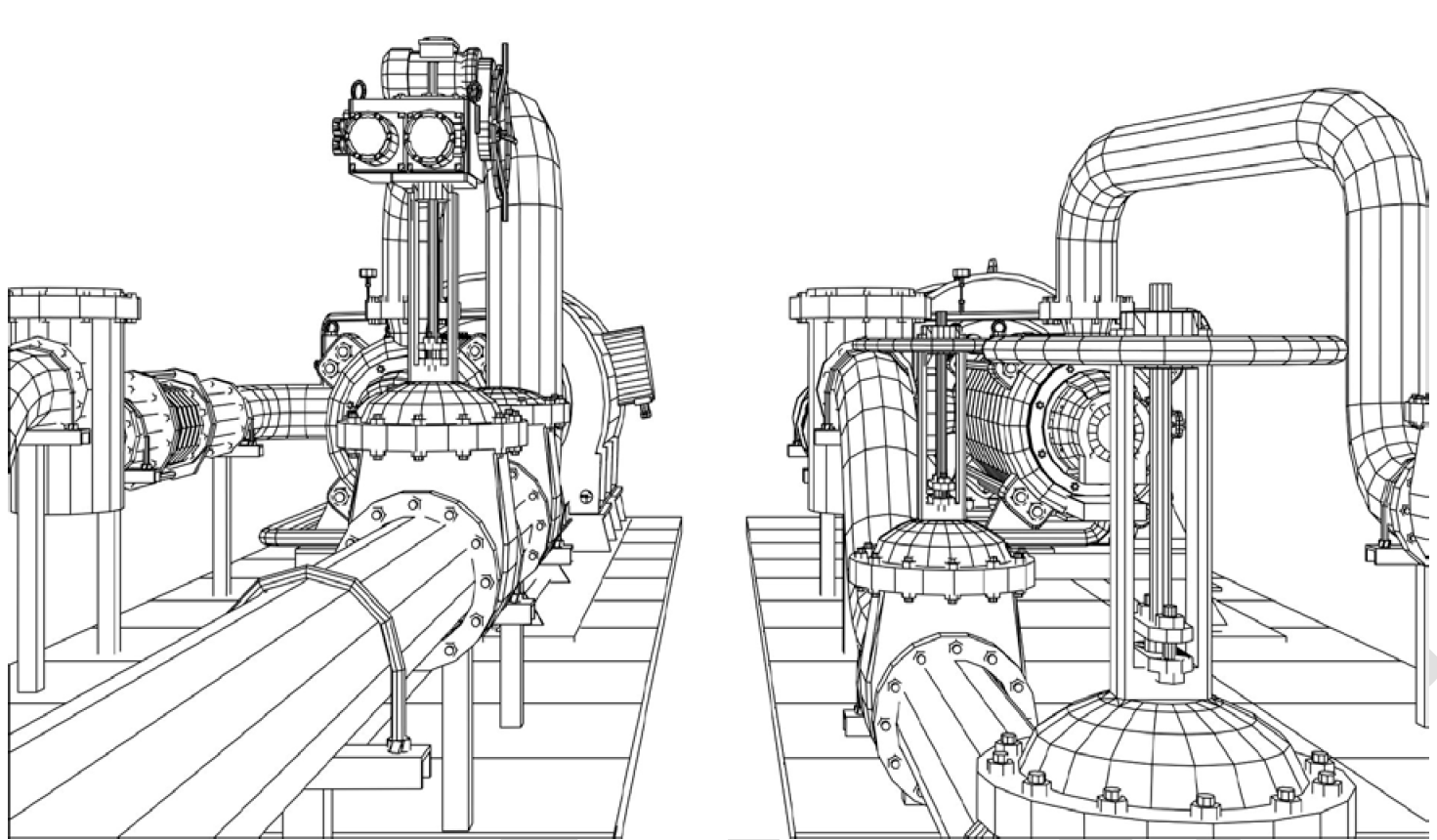

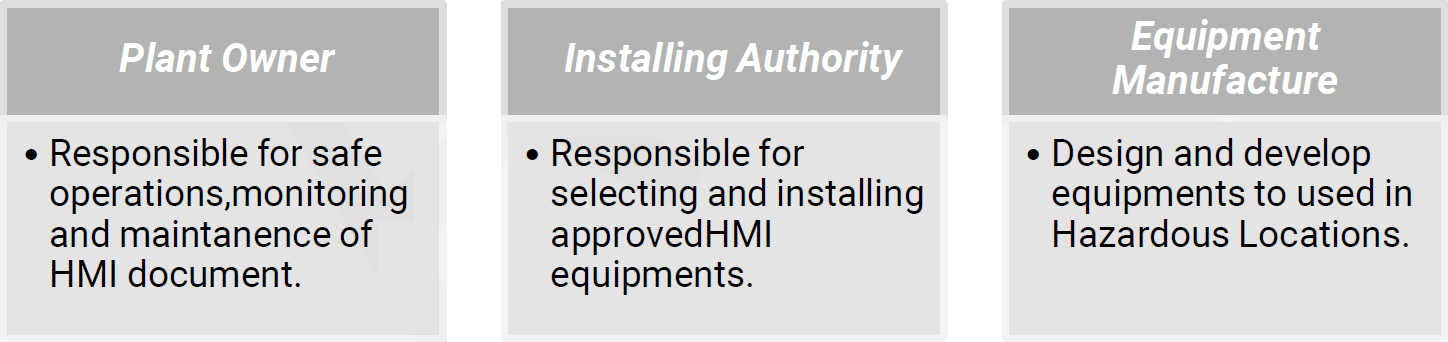

Installing and operating equipment in hazardous locations

The mission of every manufacturer, industry owner and installer is to adhere to the regulations and standards for maximum security in their facility. Specifically for hazardous locations following safety guidelines is a must, it helps in avoiding any kind of danger and potential hazard instances.

Refer to figure 4 below:

Figure 4

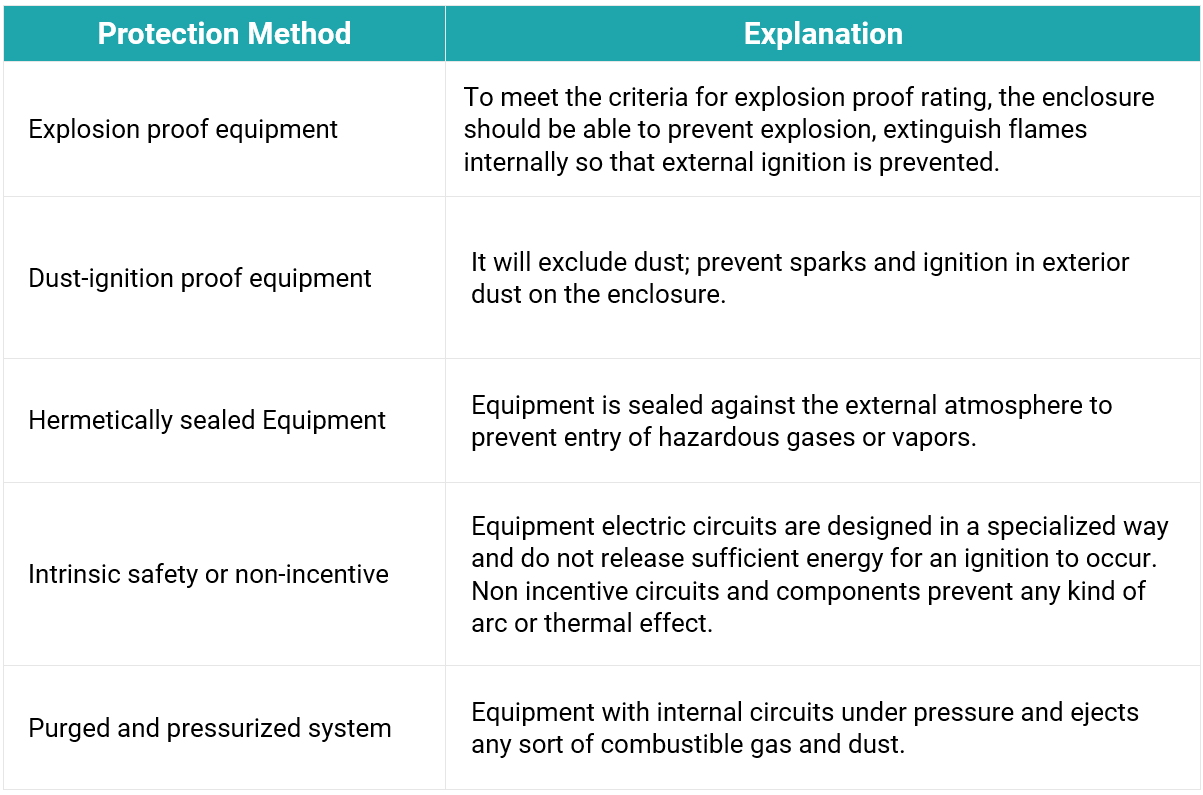

Protection Techniques: Hazardous Area

A hazardous area can be defined as any industrial space with the presence of three fundamental components: flammable substance, oxidizer, and source of flame/ignition. Hence such areas require specialized equipment to prevent and avoid an explosion. This might sound like a straightforward process but it isn’t, these are guided by regulations, guidelines, and laws which are already discussed above in this paper.

The National Electrical Code (NEC), National Fire Protection Association, OSHA has set up benchmarks for hazardous area explosion protection. North America region Factory Manual (FM) and Underwriters Laboratories (UL); and Canadian Standard Association (CSA) for Canada are the certifying agencies, recently the two of them are working together on implementing programs to be made valid in both countries.

Electrical equipment to be used in hazardous areas should be installed with one or more protection techniques for proper and secure operations. As mentioned earlier, there are several methods by which equipment can be made flame and explosion-proof, limiting energy and other sources.

Refer to the figure below for a detailed explanation.

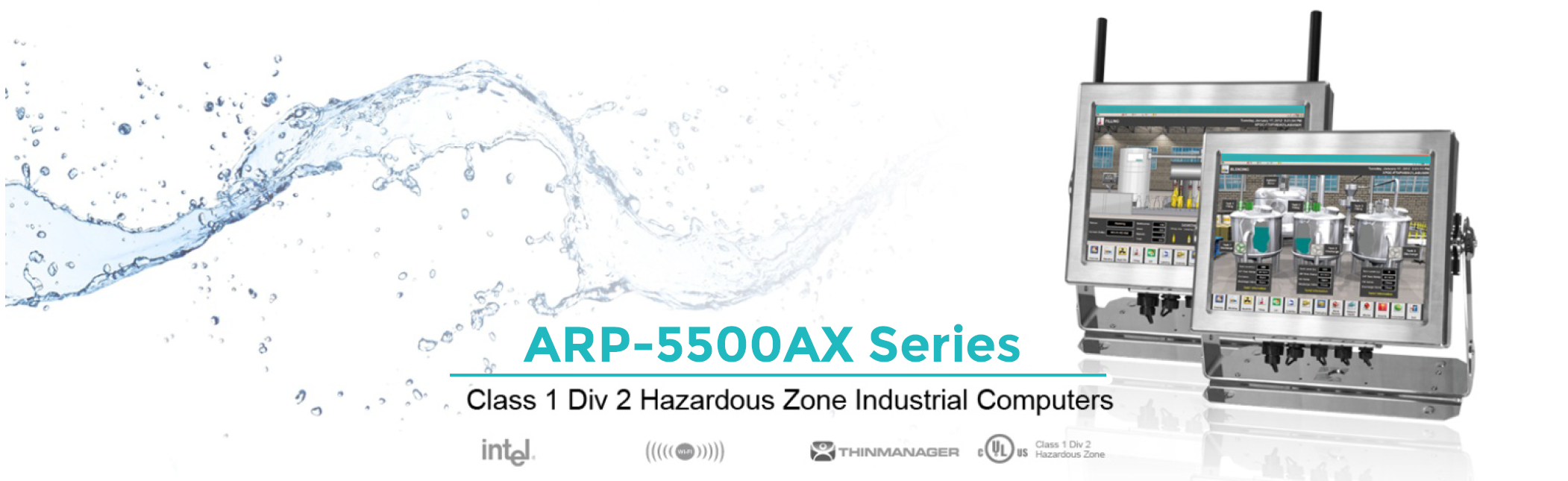

ARISTA Class 1 Division 2 Hazardous Zone TPC

ARISTA offers a wide range of panel mount and fully sealed TPC, ARP-2200AP-G00, and ARP-5500AXG00 Series, designed for use in environments where the existence of flammable gases or vapors and/or combustible dust may be a presence in the air during an abnormal occurrence such as a spill or a leak and to prevent ignition of flammable substances like gases, vapors, and liquids that are present within Class 1 Division 2 hazardous zone applications.

ARP-2200AP-G00 Series is Panel Mount TPC products family and ARP-5500AX-G00 is stainless steel fully sealed, fully enclosed TPC which has no external vents hence protect the components from gases, dust, dirt, moisture, chemicals, oil, and other external contaminants in an explosive environment. Both series are powered by Intel i7 CPU and integrated LCD display size ranging from 15", 17", 19" to 21.5". Powered by Intel i7 CPU and up to 16GB system memory and can run on Windows 64-bit operating system to meet most of SCADA/HMI applications. 21.5" Wide Screen, 16:9 aspect ratio, full HD 1920 x 1080 resolution keeps ARISTAs Class 1 Division 2 hazardous zone TPC ahead of market trend.

Both ARP-2200AP and ARP-5500AX Series have ACP Enabled Thin Client version as well. ARP-2200AP and ARP-5500AX Series ACP Enabled Thin Client version offers centralized management solutions for the factory floor, plant operational, and hazardous area locations.

ARP-2200AP-G00:

- UL/CSA Listed safety standards, non-incentive industrial panel PC for use in Class 1 Division 2 Groups A, B, C, D Hazardous classified locations.

- Panel Mount NEMA4/4X Bezel

- The HMI application meets Class I Division 2 hazardous locations (North America Classification).

- 15", 17", 19", 21.5"Active Matrix TFT LCD Display

- Black Powder Coated or Stainless Steel Bezel

- 5-Wire Resistive Touch or Tempered Glass

- Intel Core i7 Mobile

- Up to 16GB DDR3 SO-DIMM Memory

- Dual Gigabit LAN

ARP-5500AX-G00:

- UL/CSA Listed safety standards, non-incentive industrial panel PC for use in Class 1 Division 2 Groups A, B, C, D Hazardous classified locations.

- Sealed with stainless steel enclosure

- The HMI application meets Class I Division 2 hazardous locations (North America Classification).

- 15", 17", 19", 21.5"Active Matrix TFT LCD Display

- Black Powder Coated or Stainless Steel Bezel

- 5-Wire Resistive Touch or Tempered Glass

- Intel Core i7 Mobile

- Up to 16GB DDR3 SO-DIMM Memory

- Dual Gigabit LAN

ABOUT US

ARISTA is a pioneer in the industry of product development, engineering, manufacturing, and customer support. Originally formed in 1992, ARISTA has offices in China, India, and Taiwan. With years of experience and expertise in Industrial Panel PCs, Industrial monitors, Box-PCs, and Fanless embedded computers, Rack-Mount Computers, ACP ThinManager Ready Thin Clients, Embedded CPU Boards and Video Extender/Switched. ARISTA has served customers with reliability, integrity, and trust.

Disclaimer

The paper intends to give an overview of thin clients and how to incorporate them into a business. The content is for information purposes only and contains best practices to choose a thin client. In any scenario this document should not be modified, copied, or used before prior consent from ARISTA Corporation. The content in this document is subject to changed or modified any time without any obligation to anyone.